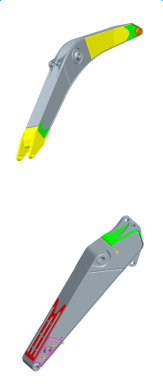

SANY SY465H excavator-Quality improvement - boom&arm

05 May,2017

Failure rate of boom within 10000 hours fells to 5%.

Failure rate of arm within 10000 hours fells to 4.8%.

Welding method is welding by both side;

The circumferential weld of medium support and side plate improved to X groove welding;

Medium side plate thickness increased from 22 mm to 25 mm;

Sheet strength increased from 235 MPa to 345 MPa.

Amount of side plate increased from 2 parts to 3 parts;

Thickness of side plate increased;

Sheet strength increased from 245 MPa to 345 MPa;

Add fully welding between medium plate and top plate to disperse force;

Change shaft sleeve form from step set to straight set;

Switch front support to forging, change the lubrication method to lubricate on both sides at the same time.

PRE:SANY SY465H excavator-Optional special configurations

NEXT:SANY SY465H excavator optimize motion trail of bucket’s bottom

Contact Us

Contact Us

Tel : 0086-10-69739318

Global Sales Hotline

Tel : 0086-731-85835199

Time : Mon–Fri 8:00 AM -17:30 PM (We will contact you within 24 hours)

Hot Page

- Three characteristics help SANY 21.5 ton medium excavator SY215C to win the market

29 Jun,2017

- Let's expect SANY to create more miracles in Indonesia

18 Mar,2017

- SANY mini excavator, a favorite of the market

24 May,2017

- Together with the world’s leading construction machinery manufacturer to capture wealth

06 Mar,2018

- SANY SY235 Excavator Dynamic Optimized Matching Control System

04 May,2017

- SANY Crawler Excavator Operating Techniques

05 May,2017

- SANY long-reach excavator series meet your needs in extended-distance operation

24 Mar,2017

- SANY Excavator machine's operating knowledge you should know

27 Apr,2017

- SANY SY235 excavators used in Swedish road widening project

02 May,2017

- SY135C in earthmoving project of mountain area

02 Mar,2017

- SANY small digging equipment 7.5 ton SY75C excavator used in road construction in Australia

18 May,2017

- SANY mechanical digger SY235C excavators used in reclamation work in Toowoomba, Australia

18 May,2017